When researching log homes, the search results are flooded with countless options and companies to consider. It can be overwhelming, especially if you are just getting started.

Understanding the difference between log home manufacturing options is an important place to start because there are significant differences between the two that can have lasting effects on the longevity of the home and resale value.

Definitions:

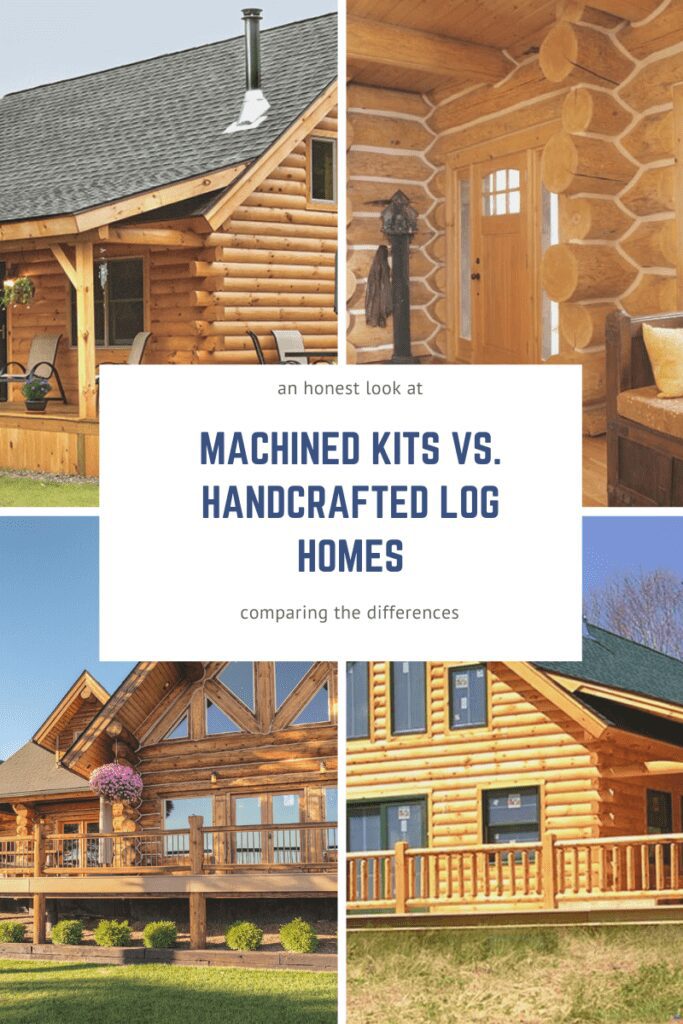

“Milled Log” Kits is the term used to describe logs individually machined to a uniform size and shape. Typically, the kit is delivered to the job site in bundles with instructions. Often customers choose a floor plan design and choose which log style they prefer. The logs kits are sold in packages and delivered to the job site unassembled. Homeowners can assemble it themselves or hire a general contractor to do it. Very little modification to the design layout can be made.

Handcrafted Log Kits refers to a process that involves hand selecting, peeling, scribing and placing each log by human log crafters. Each log is carefully scribed to fit the adjacent log. As each log is crafted the house is pre-assembled until the house is fully built. Then the logs are marked and disassembled for shipping. Floor plan options are offered by handcrafted log home companies, but because their log kits are custom built modifications are easier to implement.

First Glance Differences:

When comparing milled log cabin homes to handcrafted log cabin homes there are clear differences, some of which can effect the quality of the home years later.

Milled kits are wonderful options for budget-conscious consumers, especially on log sizes under 12” in diameter. They also offer a uniform “cookie cutter” look which may appeal to some buyers. For homeowners looking to build their own house, milled kits can often be a better option than handcrafted options because it can be simpler construction.

Some downsides to machine-milled log home packages, in many cases, are the same as the positives. For example, perhaps buyers prefer a more rustic natural look compared to the “cookie cutter” appearance. As far as pricing is concerned, oftentimes handcrafted log homes are more comparable and sometimes even less expensive in homes with 12” and greater diameter logs. For the do-it-yourselfer who yearns to build his or her own log home, handcrafted is still an option, but it usually requires a crane because the logs are heavier.

When choosing to build a handcrafted log home you can expect your custom home is meticulously crafted. Each log is selectively chosen for its placement and then hand peeled. Each notch is scribed with precision to tightly fit the adjacent logs. As this process is done, the home is carefully constructed. This detailed process does take several months. Because milled kits are machined they do take less time to construct; therefore, if time is of the essence, a milled kit could be an advantage.

Does log diameter make much difference?

The only plus side to small diameter logs is the cheaper cost factor. Otherwise, there are much greater benefits to using 12” and larger log diameters. Thermal retention properties increase with log size, in other words, the larger logs are more energy efficient.

Larger logs are also stronger structurally due to the higher overall fiber count. Just like a rope is stronger than a string, the added strings of fiber make a stronger structure.

In addition to log diameter, log length is another variable that changes by log home company. Machine-milled log builders and some hand-crafted log homebuilders keep the log lengths to around 20’ which causes butt-joints. A butt-joint is when two ends of logs are simply placed next to each other creating vertical lines on a wall. From an engineering perspective, butt-joints are not very stable because they are not very tight and they have the potential to separate once the logs settle.

Another common difference you’ll find among all log kit builders, both milled and handcrafted, is the wood species they use. In the end, all companies typically use a species that is easiest for them to attain because it is close to their base operation. Click here for a more dynamic breakdown of fiber differences.

The Finer Points

There are additional differences between milled kits and handcrafted log home kits some of which are not as important upfront as they are in the quality of the home years later. Full round logs that have been debarked still have the outer cambium that protects the log from moisture. When a log is milled the cambium is lost exposing the inner grains which are moisture absorbing. Logs naturally absorb water on the ends. Imagine numerous straw-like tubes running the length of the log; their job was to carry water from the roots to the leaves. The job of these tubes’ has always been to absorb and transfer water. Milling the logs down exposes these tubes and over time this causes the home to deteriorate more rapidly than a full-size round-log home. Note, this same cambium disruption occurs in dovetail-style log home construction no matter the log size; therefore, dovetail log homes are not as well protected as round logs.

Oftentimes, mills use logs of all shapes and sizes, sometimes even using crooked logs. One would think this would not matter since it is milled to exact specifications; however, crooked logs can have fiber displacement and they are prone to twist during settling. This too can have lasting effects.

Another key component many people don’t think about is resale value. Full log homes retain their value more than milled kits. When it comes to reselling a log home, there is a lot of confusion about finding comparable houses for comparison. The debate has been ongoing for decades and sadly is often the reason buyers don’t get approval on existing log homes or log home construction loans. Because milled packages are prefabricated and then shipped as a “kit,” they are usually considered a pre-manufactured home and sometimes appraisers use manufactured homes instead of stick-framed homes as comparables which lower the value. Whereas handcrafted homes are usually set up by the manufacturer on the job site and can be compared to other stick frame houses. In reality, it really boils down to the appraiser and what they consider a qualified comparable. It is a variable that can change from person to person.

Common Mis-Information

There can be so much conflicting information on the internet making it hard to know who to trust and what to believe.

We’ve heard that milled kits are more energy efficient than handcrafted log homes and this may be true when compared to a handcrafted log home that was poorly done or that was built with green logs. The truth is that when you use a company that specializes in handcrafted log cabin homes and only uses fully dried logs, the energy efficiency comes from the size and fiber density of the log, not the construction style.

Another common misconception is that air drying is better than kiln drying. The truth is that dry is dry, how it came to be that way matters very little except with white wood species. That species of wood does not do well in kilns and is better as air dried because it needs to be dried too slowly to make kiln drying practical.

The Caribou Creek Difference

Since we have given you an objective comparison of milled versus handcrafted log homes, we wanted to take a moment to share with you some things that set Caribou Creek apart from other handcrafted log home companies. These differences are specific to Caribou Creek and not all handcrafted log home companies have these standards, although some may.

No butt-joints or butt and pass corner joints: When we craft a home we make sure the logs go the full length of the wall without any splices. In our opinion, these splices not only deter from the aesthetics of the home but also can become bothersome later because the logs don’t always settle the same which can cause a lip at the joint.

We mentioned that log home companies typically use the wood species that is easiest for them to acquire. Caribou Creek will build with any species if a customer truly has a preference; however, whenever possible we recommend Douglas Fir from the Oregon coast. Although coastal Douglas Fir is 800 miles away round-trip from our facility, we go the extra mile to acquire it because we have found, for full log diameter structures, it offers higher quality straighter logs with minimal flaws. We are extremely picky about the logs we buy. So much so, that we don’t even use the standard grading system because we found we still threw out many of the logs we were getting. Over time we have found log suppliers that understand our standards and only offer us the highest quality fiber.

As you begin getting bids for your dream log cabin home project you may find that some companies seem less expensive than Caribou Creek. Oftentimes this is because other companies will up-sell customers. They start with a very low price and then offer upgrades. Upgrades such as cut-out windows and doors, electrical and plumbing outlets, and even roof structures are some of the more common ones. Some companies even offer a low price, but then charge an exorbitant price for reset (restocking the kit on site) making up some of their loss. These are just some of the practices we have witnessed after being in business since 1989. Caribou Creek is not interested in doing business this way. When we bid on a project we include cutouts for windows, doors, electrical & plumbing chases, as well as roof structures. We do price the reset separately because it is an option for our clients; however, we do not try to make up any lost profit. We have found that doing business honestly is the best decision for all parties, and creates the least amount of trouble later on.

If you are considering a log home schedule a free consultation call today. We are happy to answer any questions you may have. Consider purchasing your copy of our “Ultimate Log Home Planning Guide” to help you map out your dream home!